GRC

(GRC) Glass Reinforced Concrete

What is GRC?

GRC means Glass Reinforced Concrete

Glass reinforced concrete (GRC) is a type of concrete that incorporates alkali-resistant fiberglass in place of traditional steel mesh or rebar. This makes the concrete much lighter and more Eco - friendly, without loosing any of its strength. Glass reinforced Concrete is increasingly being used for commercial and residential projects. Glass reinforced concrete is a relatively new type of concreting product that can give you more flexibility with your designs while still being as strong as traditional concrete.

We modified GRC into Water resistant GRC plaster

Where to Use?

- Use at new construction building Exterior

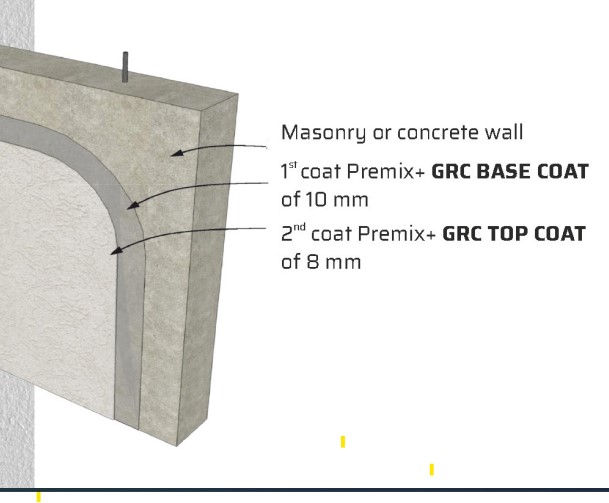

Wall Plaster, for best result apply 2 coat of plaster,

- 1st is GRC Base Coat and

- 2nd is Premix+ GRC Top Coat

- Also use for repair work of Interior

- and Exterior walls, to fill thecracks, joints and re plastering work.

- GRC plaster is a cost effective option for creating intricate architectural features that are lightweight and corrosion free.

- GRC is as hard wearing as standard concrete it used in many locations, outdoors, from seating to garden ornaments.

How to Use?

- Clean the surface from oil, dust, bound inhibiting agents

- Add Water approximately 15 to 17 ltrs. per bag

- Mix Mortar properly for better result

- Wait 2 to 3 min. to dissolve the additives

- Curing after 24 hours, 2 times per day for 5 days

Direction to Use?

- Clean the surface from oil, dust, bound inhibiting agents

- Add Water approximately 15 to 17 ltrs. per bag

- Mix Mortar properly for better result

- Wait 2 to 3 min. to dissolve the additives

- Curing after 24 hours, 2 times per day for 5 days